Over the years Rocksoil S.p.A. has developed design and construction technologies that have rapidly come to the attention of those who work in the field of geo-engineering.

ADECO-RS

The Analysis of Controlled Deformation in Rocks and Soils (ADECO-RS), the crowning point of long in-depth research into the stress-strain behaviour of more than 1,000 km. of tunnel and more than 9,000 faces, is a design and construction approach developed by Rocksoil S.p.A..

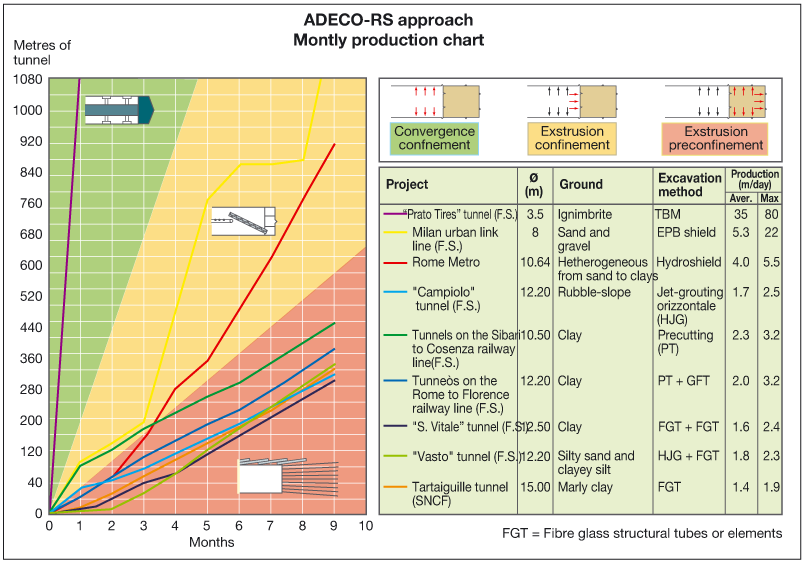

The ADECO-RS approach makes a clear distinction between the design and the construction moments, allowing reliable forecasts of construction times and costs to be made. It uses the advance core (the core of ground ahead of the face) as a structural tool for the long and short term stabilisation of tunnels, after its rigidity has first been regulated by means of conservation techniques. Tunnels can consequently be driven in difficult stress-strain conditions to predetermined safety standards with precise scheduling and industrialisation of operations.

The excellent results achieved have induced major Italian clients (Autostrade S.p.A., A.N.A.S., ITALFERR SIS T.A.V. S.p.A.) to adopt the ADECO-RS approach in their specifications and norms. The tunnels on the new Bologna to Florence and Rome to Naples High-Speed rail lines have been designed and are being constructed on the basis of the ADECO-RS approach.

This new way of constructing tunnels has also aroused considerable interest abroad where it was chosen for the construction of the difficult Tartaiguille tunnel (Marseilles to Valence railway line).

By using the ADECO-RS approach, to industrialize tunnel excavations is possible in the most difficult grounds too

This new way of constructing tunnels has also aroused considerable interest abroad where it was chosen for the construction of the difficult Tartaiguille tunnel (Marseilles to Valence railway line).

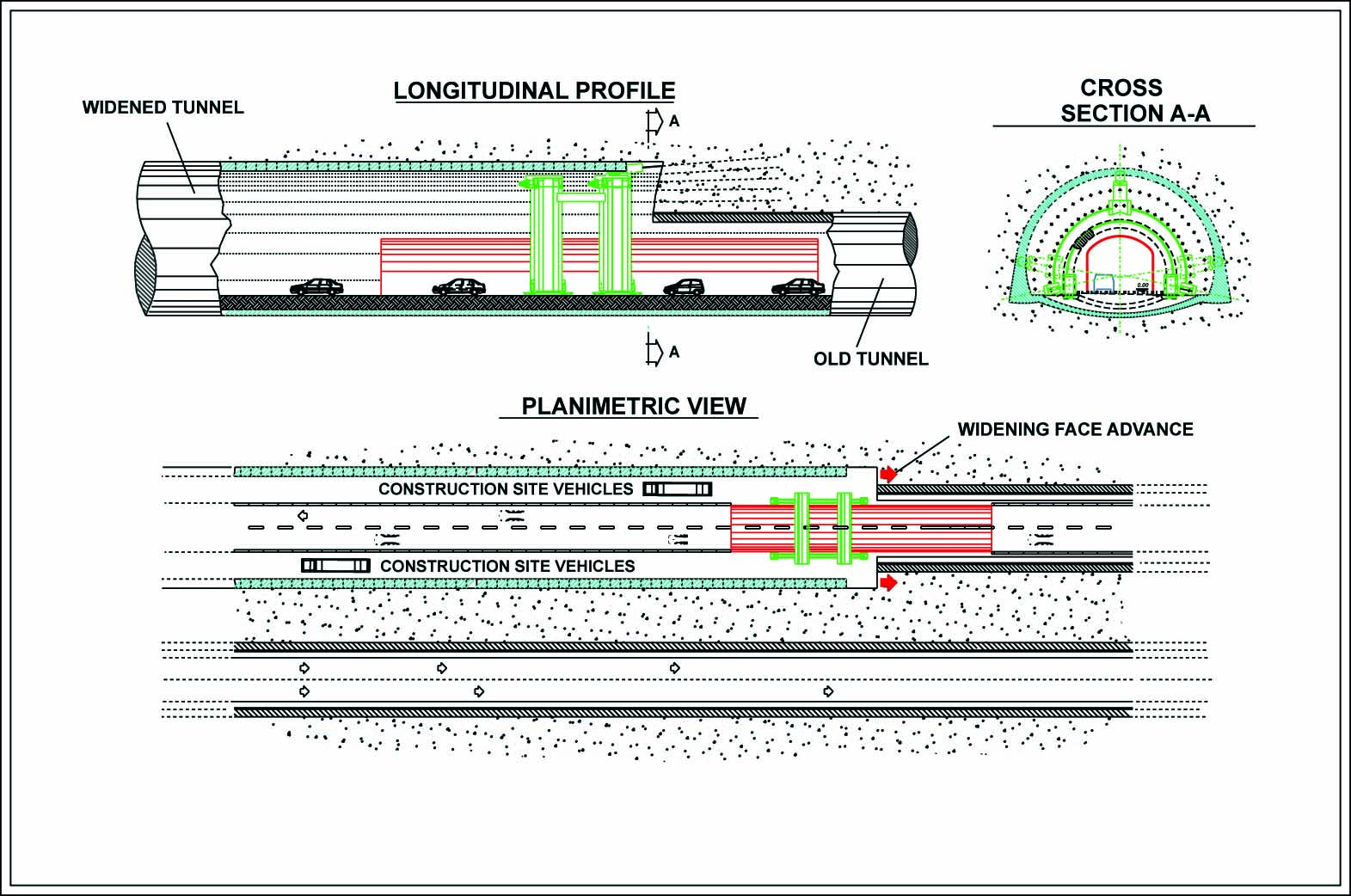

Widening of tunnels without interrupting traffic

With the increasing demands of traffic, it is more and more frequently necessary to widen roads motorways and rail tracks to increase their capacity. The problem becomes difficult if not impossible when the routes run through tunnels unless resort is made to costly additional routes with the creation of new tunnel arches to add to the existing ones.

Rocksoil S.p.A. has researched and developed special new technology which by making judicious use of the "active arch" principle and modern conservation systems, allows routes to be widened and all works to be carried out while traffic runs in safety under a protective "steel shell".

This technology was employed to widen the "Nazzano" tunnel, on the Rome to Naples motorway, from two to four lanes in each direction. Particular features include its extreme versatility, since it can be employed in a great variety of ground and stress-strain conditions and the high degree of mechanisation of works that can be achieved with a consequent regular rhythm of tunnel advance and reduction in construction times, all factors with positive repercussions on site budgets and advance rates.

Following the success in Nazzano, the new technology is now applying for enlargement in the presence of traffic of the ''Montedomini'' tunnel (Motorway A14, near Senigallia).

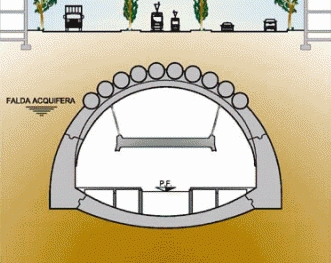

Cellular Arch

Each year the American technical journal, Engineering News-Record published by McGraw-Hill, nominates a man of the year in the construction field. In 1990, Prof. Pietro Lunardi was included as one of those who had contributed with his ideas to the achievement of significant progress in the construction field, "he invented the 'Cellular arch technique' to excavate wide span underground caverns in cohesion-less ground".

This original construction system can be employed to drive bored tunnels with very shallow overburdens up to a diameter of 60 m. in very poor ground without causing surface subsidence.

One significant application of this system was for the construction of the Venezia Station on the Milan Urban Link Line. A cavern 30 m. in diameter and 270 m. in length was bore tunnel excavated right in the centre of the city with an overburden of only 4 metres and under the water table.

Excavation by T.B.M.

The experience and suggestions of a design engineer who is a genuine expert in tunnel construction are essential to those who construct tunnel boring machines (TBMs), as they compete with each other to produce increasingly more flexible and efficient shields and cutters. To achieve this Rocksoil S.p.A. has always co-operated with major producers of machines who have asked for opinions and suggestions.

A new generation of shielded TBMs has been born from the close co-operation between Rocksoil and Herrenknecht. They allow the rock mass to be surveyed continuously in real time and ground improvement to be performed in advance where necessary.

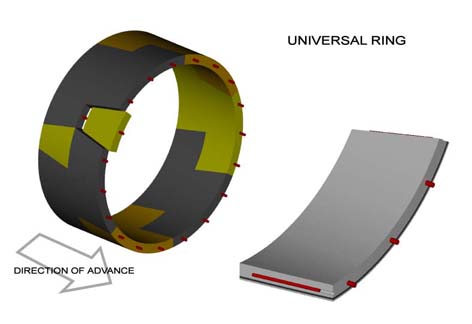

Advanced study and experimentation in the field performed by Rocksoil on prefabricated concrete segment linings are of great importance in this respect for recent developments in mechanised excavation and Rocksoil is the firmly acknowledged world leader in this field with the development of the “Universal Ring” and special concretes and additives.

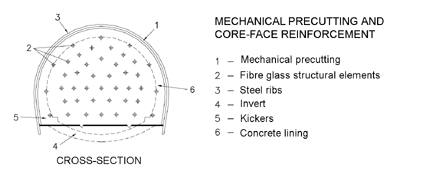

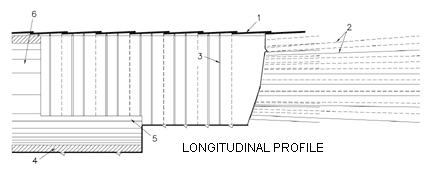

Mechanical pre-cutting and core-face reinforcement by-means of fibre glass structures

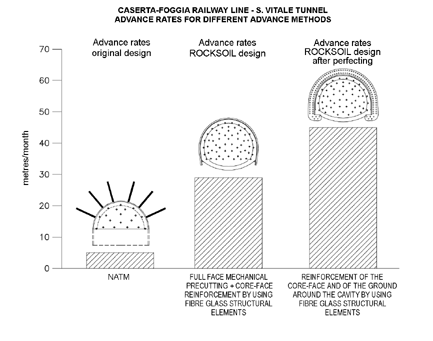

Full face mechanical precutting and ground improvement of the advance core using fibre glass structures are both construction technologies developed by Rocksoil S.p.A. between 1986 and 1988. They have both solved once and for all the problem of tunnelling in ground with a clayey matrix of very poor geomechanical quality susceptible to chemical and physical weathering.

The large number of tunnels which had previously posed serious problems to designers and constructors and that have now been completed with success, demonstrate just how effective these new technologies are. Used together they have resulted in constant and safe tunnelling with excellent advance rates (2.75 m./day full face) even in situations of extreme instability which would otherwise not have allowed any advance.

Jet-grouting

Rocksoil S.p.A. researched and developed horizontal jet-grouting systems to improve ground during tunnel advance in ground with poor cohesion, together with similar systems applied vertically for foundation shafts and tunnel portals in unstable slopes, in the second half of the 1980's.

They are currently deemed irreplaceable for working in ground subject to difficult stress-strain conditions if subsidence and undesirable deformation phenomena are not to be triggered.

Special features of these systems include the ability to schedule operations and operational safety.

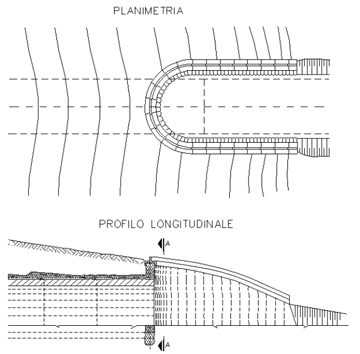

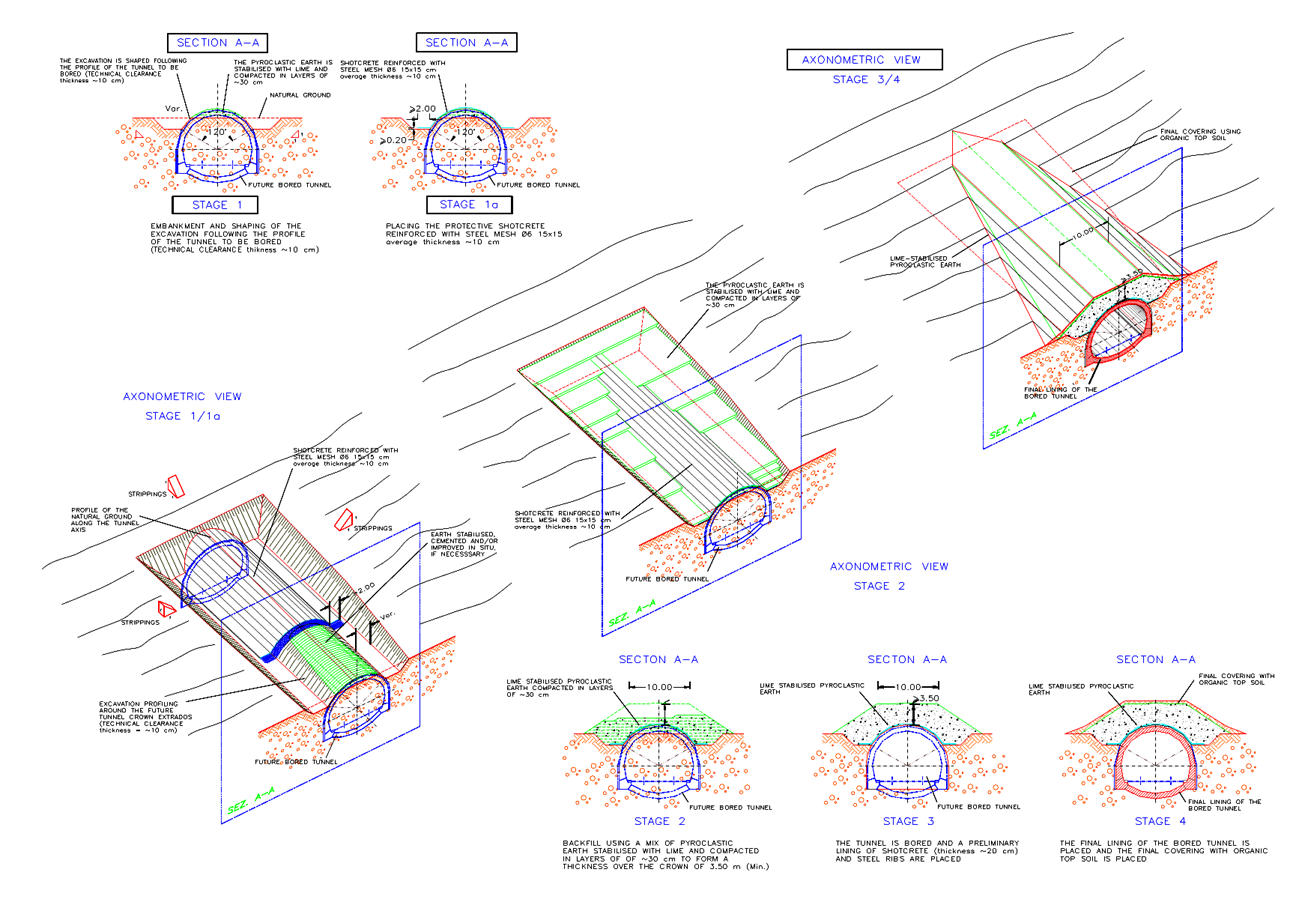

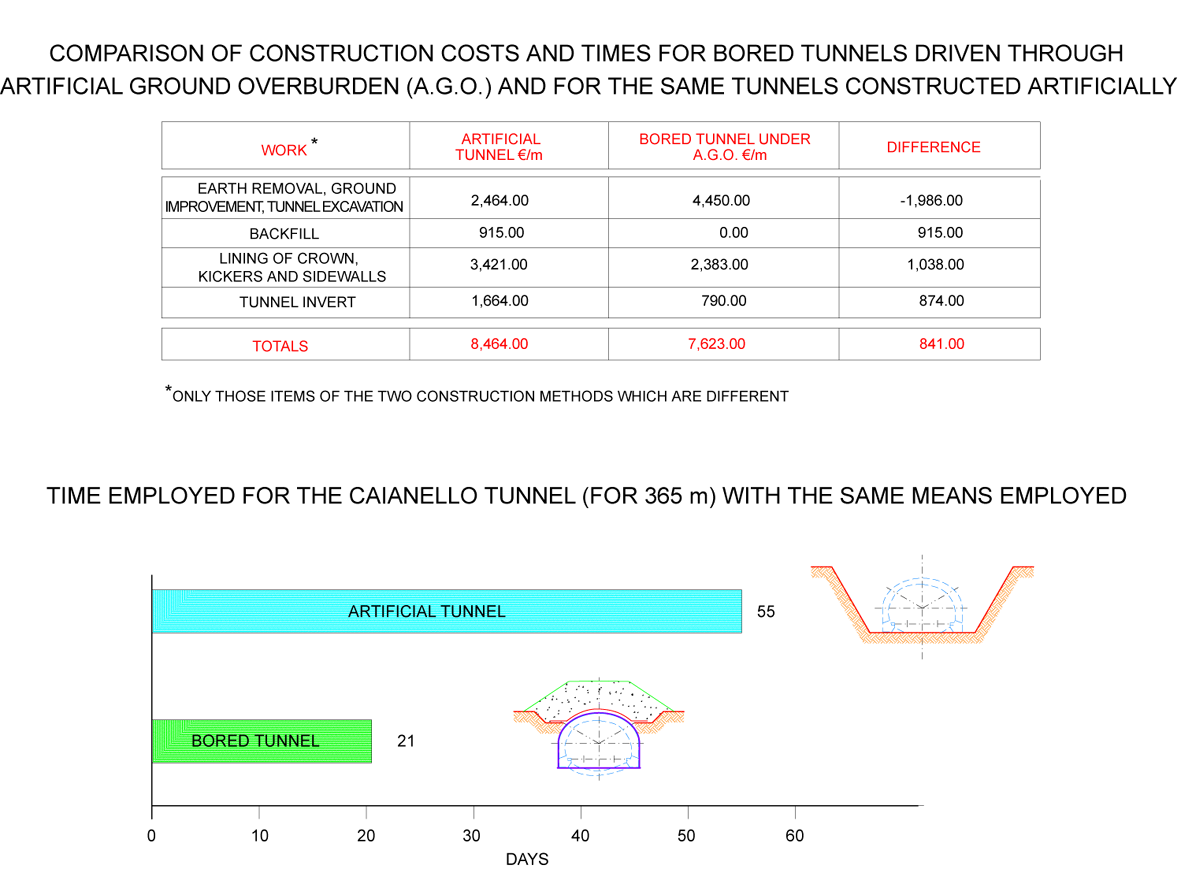

Artificial Ground Overburdens (A.G.O.) to bore tunnels without sufficient cover

The construction of artificial tunnels to cross lengths of a route in which there is insufficient overburden for bored tunnel advance inevitably involve deep incisions into the slopes to be crossed with consequent problems of safety and environmental impact.

Rocksoil S.p.A. researched and developed the use of special "artificial overburdens" of improved ground created over the crowns of tunnels before excavation. They can then be bore tunnel driven thereby by-passing all the problems connected with traditional methods of constructing artificial tunnels.

This new method has been used for the construction of approximately 1.5 km of tunnels on the new Milan to Naples and Bologna to Florence High Speed railway lines. It was found extremely practical and safe, not to mention economical and environmentally sound.

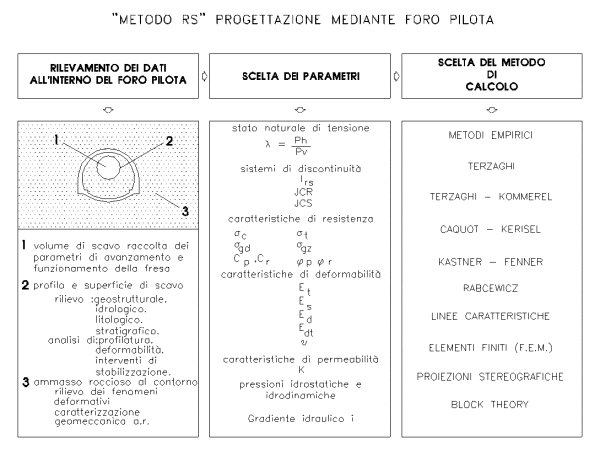

RS Method

Resort to a small diameter exploratory drift before widening to full face excavation as a survey and experimental method of advance in particularly uncertain ground has been known to tunnelling specialists for some time. By fully exploiting the availability of modern boring machinery capable of driving tunnels in heterogeneous ground Rocksoil S.p.A. has incorporated the pilot tunnel as a truly integral part of tunnel design in the ADECO-RS approach.

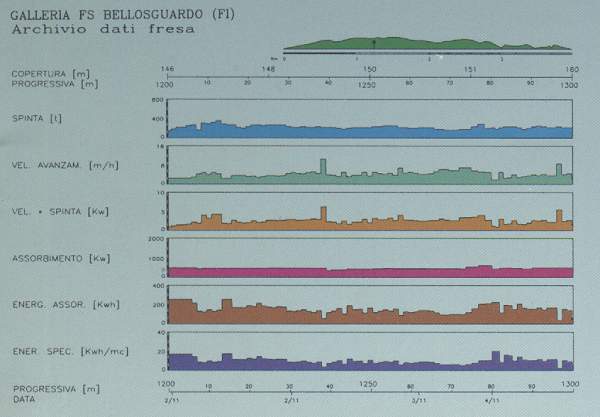

One particular feature of the "RS Method" is the use of T.B.M.'s as huge penetrometers which measure machine parameters (thrust, advance velocity, absorbed power, etc.) for the purpose of determining the specific energy employed per cubic metre of material excavated and this is in turn correlates with the strength of the rock mass.

More than one hundred kilometres of tunnel have been driven to date using this new system of designing and constructing tunnels, in full respect of forecast construction times and costs. It has certainly passed the baptism stage.

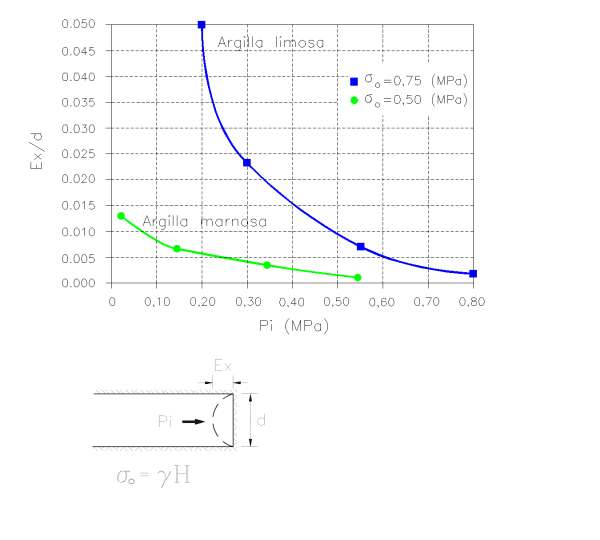

Extrusion tests in triaxial cell

Extrusion tests performed in triaxial cells were researched and developed by Rocksoil S.p.A. to study the probable deformation response of a tunnel to be constructed under difficult stress-strain conditions.

A test sample from rock or soil is inserted into the cell and the original stress state of the ground is recreated.

By maintaining the stress state around the sample constant and progressively decreasing the state of stress inside the extrusion chamber, the change in the stresses induced by tunnel advance is simulated and an estimate of extrusion at the face as a function of time or of internal pressure is obtained.

From an analysis of the extrusion curves obtained with this method, it is possible to make reliable predictions of the stress-strain behaviour of a tunnel during excavation and to design conservation procedures that may be indispensable to the success of the tunnel.